Esimeni esiguqukayo njalo sobuchwepheshe bebhethri, ukuthola umshini wokushisela ofanele kubalulekile ezinqubweni zokukhiqiza ezisebenzayo nezisebenzayo. U-Styler, umholi kubuchwepheshe bokushisela, unikeza uhla lweizixazululo ezihambisanayoezinhlotsheni ezahlukene zebhethri nezidingo zokukhiqiza. Kulo mhlahlandlela ophelele womthengi, sizozulazula ezintweni ezibalulekile ukuze sikusize ukhetheumshini wokushisela ophelelengokwezidingo zakho.

1. Nquma Uhlobo Lwebhethri

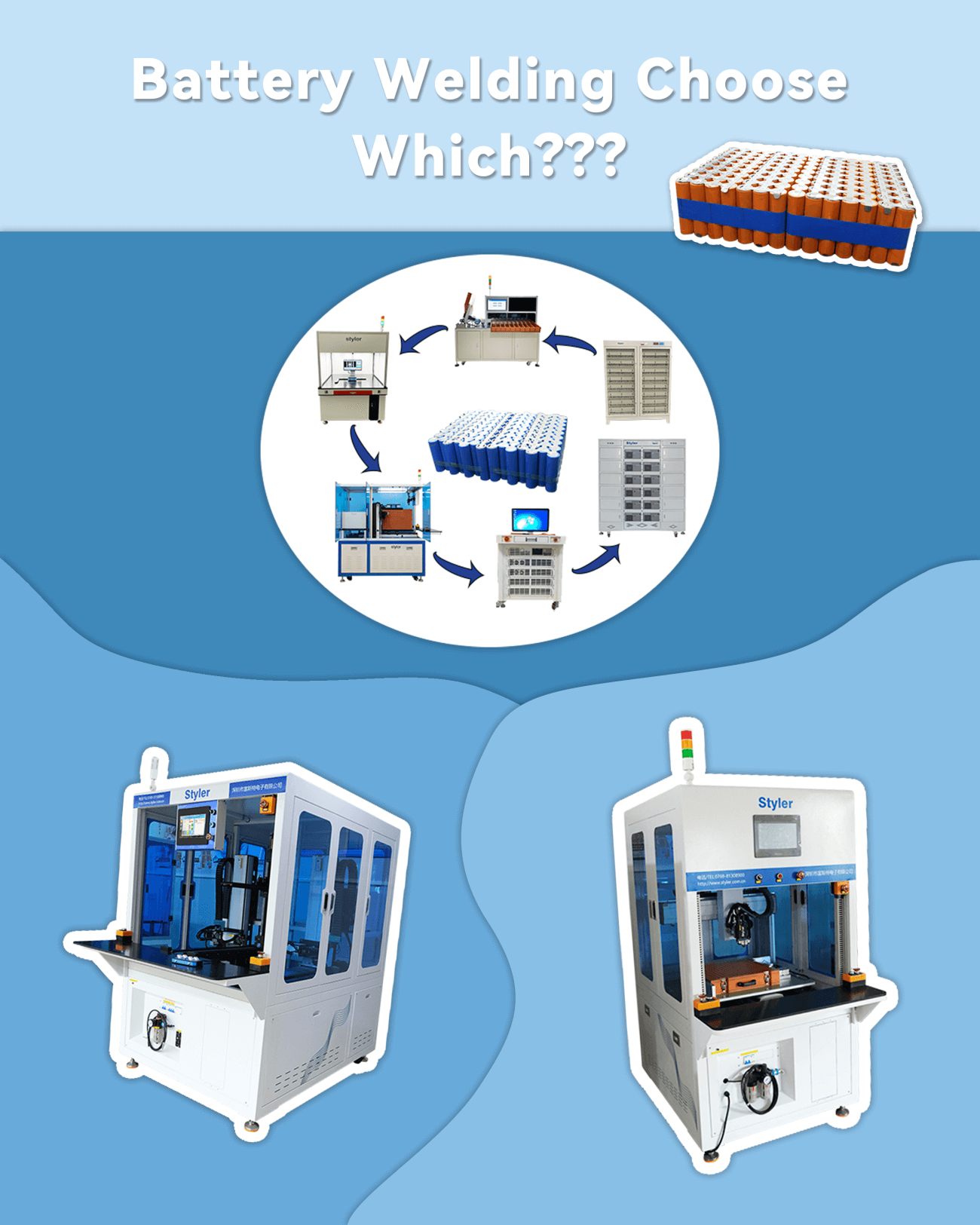

Ngaphambi kokuthi ungene emhlabeni wemishini yokushisela, kubalulekile ukukhomba uhlobo lwamabhethri ozobe usebenza ngalo. Kungakhathaliseki ukuthi i-cylindrical, prismatic, noma amanye amafomethi akhethekile, i-Styler inezixazululo eziklanyelwe ukuhlangabezana nezidingo eziyingqayizivele zalelo nalelo.

2. Qinisekisa Welding Materials

Izinhlobo zebhethri ezihlukene zidinga izinto zokushisela ezithile ukuze zisebenze kahle. Kumaseli ayi-cylindrical, i-nickel-plated noma imichilo ye-nickel emsulwa esukela ku-0.1mm ukuya ku-0.5mm ivame ukusetshenziswa. Ngakolunye uhlangothi, amaseli e-prismatic ngokuvamile asebenzisa amathebhu e-aluminium asukela ku-1mm kuya ku-3mm ngogqinsi. Imishini kaStyler ihlomele ukuphatha lezi zinto ngokunemba nokwethembeka.

3. Hlola Ukukhiqiza

Umthamo wokukhiqiza udlala indima ebalulekile ekukhetheni umshini wokushisela ofanele. Ngokukhiqizwa kweseli ye-cylindrical enevolumu ephansi, uchungechunge lwe-Styler's PDC/IPV/IPR lwe-IPR luhlinzeka ngokuguquguquka nokulawula. Ngokukhiqizwa kwevolumu ephezulu, cabanga ngemishini yokushisela ye-Styler's XY ezenzakalelayo yohlangothi olulodwa noma enezinhlangothi ezimbili. Izinketho zokwenza ngendlela oyifisayo njengamakhanda ajikelezayo nezinto ezilungiswayo ezifanelana nosayizi webhethri lakho zithuthukisa ukusebenza kahle nokusebenza. Ngokushisela amaseli e-prismatic, imishini yokushisela ye-laser ye-styler ye-gantry galvanometer inikeza izinketho zamandla kusukela kuma-watts angu-1000 kuya kwangu-6000, iqinisekisa ukuhambisana nezinto ezihlukahlukene zamathebhu nogqinsi.

4. Hlola Pack Assembly Solutions

Ngaphezu kwemishini yokushisela, i-Styler inikeza izinsizakalo zokwenza ngokwezifiso umugqa wephakethe we-semi-automatic futhi othomathikhi ngokugcwele. Ithimba lethu elizinikele le-R&D lisebenza eduze nawe ukuze liklame izixazululo zomugqa wokuhlanganisa ezihambisana nezidingo zakho, isabelomali, kanye nemikhawulo yendawo. Kusukela kumqondo kuya ekusetshenzisweni, i-Styler inikeza ukwesekwa okuphelele ukuze wenze lula inqubo yakho yokukhiqiza iphakethe lebhethri.

Ukukhetha umshini wokushisela ofanele kubalulekile ekuzuzeni ukukhiqizwa kwebhethri okungenamthungo nokusebenza kahle. Ngohlu oluhlukahlukene lwezixazululo ze-Styler ezakhelwe izinhlobo ezihlukene zebhethri namavolumu okukhiqiza, ungaphakamisa amakhono akho okukhiqiza ngokuzethemba. Kungakhathaliseki ukuthi usebenza ngezinga elincane noma umdondoshiya wemboni, uStyler unolwazi nobuchwepheshe ukuze uhlangabezane nezidingo zakho zokushisela. Xhumana nethimba lethu namuhla ukuze liqale uhambo oluya ekukhiqizeni okuthuthukisiwe kanye nekhwalithi ekukhiqizeni amabhethri.

Ulwazi olunikezwe nguStylerkuhttps://www.stylerwelding.com/eyezinjongo zolwazi kuphela. Yonke imininingwane ekuSayithi inikezwa ngokwethembeka okuhle, nokho, asenzi izethulo noma iwaranti yanoma yiluphi uhlobo, okuvezayo noma okushiwo, mayelana nokunemba, ukufaneleka, ukuba semthethweni, ukwethembeka, ukutholakala noma ukuphelela kwanoma yiluphi ulwazi kuSayithi. NGAPHANSI KWESIKHATHI NGEKE SIBE NESIBOPHO KUWE NGOKULAHLEKILE NOMA UMONAKALO WANOMA YILUPHI UHLOBO OKWENZEKA NGENXA YOKUSETSHENZISWA KWESIZA NOMA UKWETHEMBELA KUNOMA YILUPHI ULWAZI OLUNIKEZELWE KUSAZI. UKUSEBENZISA KWAKHO INDAWO NOKUTHEMBELA KWAKHO YILUPHI ULWAZI ESIWULWENI KUSENGOZINI YAKHO KUPHELA.

Isikhathi sokuthumela: May-24-2024